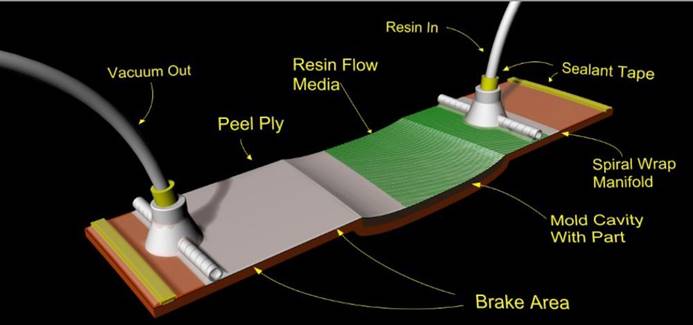

What’s Vacuum Infusion?

Put simply, it’s the process of injecting resin into a composite system to fill the laminate without the need for an oven or tooling. What makes Vacuum Infusion a total solution for composites manufacturing is that the process is optimized for factors such as resin volume, flow rate, and proper air removal from the extremities of the part. What’s more, there are virtually no emissions with Vacuum Infusion, making it one of the most environmentally friendly processes in today’s work environment. To help marine manufacturers learn how the Vacuum Infusion Process can help them build composites parts better, faster and with less waste.

It’s ideal for manufacturing large parts for a variety of applications, including boat hulls and decks for the marine industry.

One of the most important criteria for achieving high quality parts through Vacuum Infusion is having the right process materials on hand. That’s where Ninezerotech can help.

Products include:

• Peel ply

• Spiral Wrap Manifold

• Resin hoses